In precision manufacturing, almost all metalworking operations now involve CNC (Computer Numerical Control) technology, a testament to its revolutionary impact. This cutting-edge machinery has transformed the manufacturing landscape, transcending the limitations of conventional techniques. CNC machining is not just about creating items; it’s about sculpting dreams into reality with unparalleled accuracy.

According to Fortune Business Insights, the global CNC (Computer Numerical Control) machine market is expected to increase from USD 86.83 billion in 2022 to USD 140.78 billion by 2029 at a (CAGR) of 7.1% during the forecast period.

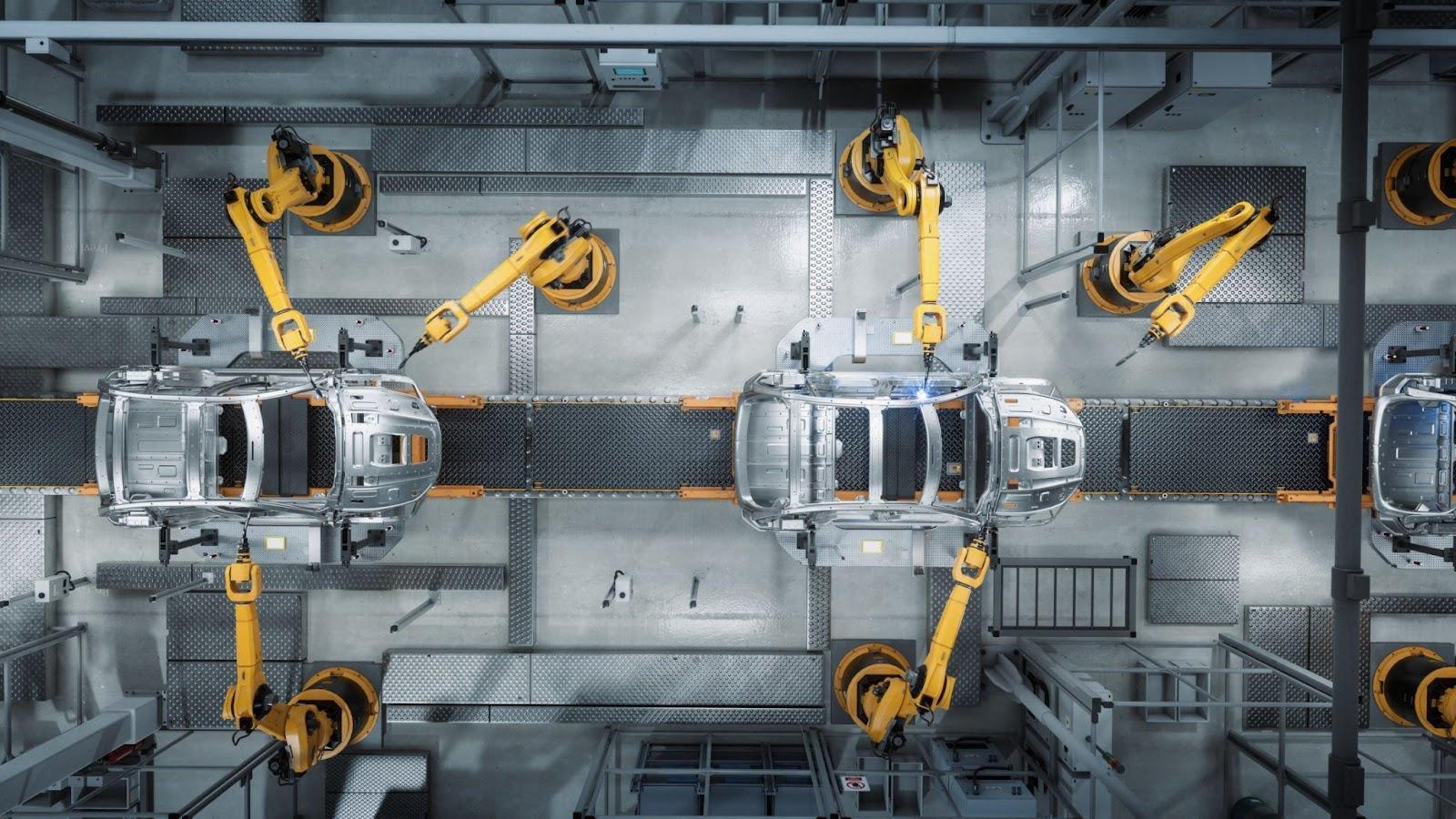

It represents a monumental shift from traditional, manually intensive processes to an era where complex designs are executed flawlessly at the touch of a button. The transformation brought by CNC machining is evident across industries, offering a blend of precision, efficiency, and innovation that reshapes how we think about production in the 21st century.

What is CNC Machining?

CNC Machining, short for Computer Numerical Control, is a manufacturing process where computers control machine tools. It’s like giving machines a set of detailed instructions on what to do. Imagine a robot that can carve, cut, or shape materials with incredible precision, following commands from a computer program.

Unlike manual machining, where a person guides the tools, CNC relies on digital blueprints. The machines, often milling machines or lathes, can create complex parts needed for cars, airplanes, or even delicate medical equipment.

This method ensures each part is identical, reduces errors, and can work on different materials, like metal or plastic. It’s technology making things with amazing accuracy!

Advantages of CNC Machining

Here are some of the key advantages of CNC machining:

1. Enhanced Precision with Accuracy

CNC machining stands out for its remarkable precision and consistency, much like a robot faithfully executing its instructions without errors. Unlike manual craftsmanship, which can vary, CNC machines follow exact computer directives.

Imagine a robot programmed to meticulously craft wooden toy cars, ensuring each is a carbon copy of the last, flawless and identical, even in complex designs.

This method’s reliability is crucial for producing vital components in fields like automotive, aerospace, and healthcare, where precision is essential, and the smallest error can have significant consequences.

2. Long Term Cost Saving

Another benefit of CNC machining is its capacity for long-term cost savings. Initially, the investment in CNC equipment might seem substantial, but it pays off.

Here’s how: the precision of CNC machines drastically reduces waste. Less material is discarded because of errors, which is a big deal, especially with expensive materials. Plus, the machines’ consistency cuts down on the need for do-overs, saving both time and resources.

Another cost-saving factor? Labour. CNC machines need fewer people to operate them, reducing labour costs. Over time, this reduced need for manual intervention means fewer hours paid for labour-intensive work.

Then there’s durability. CNC machines are robust and long-lasting, meaning less frequent replacements or repairs. In industries where production is ongoing, these machines work tirelessly, churning out parts non-stop, maximising production efficiency.

Ultimately, the blend of reduced material waste, lower labour costs, and enhanced production efficiency means significant cost savings over the long haul.

3. Scalability

CNC machining shines in scalability, which is crucial for adapting to market shifts. This technology allows for easy adjustments in production volume. Once set up, increasing or decreasing output is straightforward, avoiding costly and time-consuming retooling.

CNC maintains consistent quality and cost-efficiency for small-scale projects or large orders. It’s perfect for businesses facing fluctuating demands, offering the flexibility to swiftly scale operations up or down while keeping costs predictable and quality high.

This adaptability makes CNC machining a powerful tool for growth in dynamic markets.

4. Safety

Safety is important in the workplace, and automated machining enhances this. The hands-off operation reduces the risk of accidents since operators don’t need to be near active components. This means there’s less chance of accidents and getting hurt.

The automated nature of these machines minimises the risk associated with manual adjustments and handling during operation. Users can maintain a safe distance, enhancing safety significantly.

Plus, modern CNC machines have special safety bits and pieces like big red stop buttons, shields, and intelligent sensors that can spot and stop problems before they become dangerous.

All these things together make a much safer place for everyone working in many different kinds of jobs.

5. Boosts Production Speed and Quality

CNC machining shines in boosting production speed and quality. It’s a powerhouse that works almost non-stop, quickly turning raw materials into precise parts. This method eliminates the typical pauses in manual machining, allowing for uninterrupted work.

With its computerised precision, CNC machines churn out consistently accurate parts, reducing the need for frequent quality checks. They can multitask, too, handling various operations like drilling, cutting, and engraving simultaneously.

This efficiency means products can be completed and shipped out faster, a massive advantage in industries where time is money. This translates to meeting customer demands more swiftly and staying ahead for businesses.

Overall, CNC machining is not just about making things; it’s about making them faster, better, and with unmatched precision.

6. Quick Prototyping

One of the standout benefits of CNC machining is its capability for quick prototyping. This process turns ideas into tangible prototypes swiftly and accurately. Imagine you’re visioning up a new gadget. CNC machining takes your digital design and rapidly creates a physical model.

This speed is crucial for innovation, allowing designers to test and refine their ideas without long waits. It’s not just fast, either; CNC’s precision means prototypes closely match the final product, giving a true sense of the design’s functionality and appearance.

This quick turnaround is invaluable for businesses, significantly reducing development time and costs. Overall, CNC machining is a game-changer in prototyping, blending speed with accuracy to fuel creativity and efficiency.

7. *Reduces the Need for Manual Labour

One of the standout benefits of CNC machining is its reduced need for operators. Unlike traditional manufacturing, which demands a significant workforce, CNC machines streamline operations with their automated capabilities. This means fewer people are needed to oversee production.

For companies, this translates into substantial cost savings on labour. Moreover, CNC operators can manage multiple machines simultaneously, optimising workforce efficiency. With the machine’s precision and automation, the focus shifts from manual labour to monitoring and programming – tasks that require less physical effort and are often quicker to learn.

In businesses where paying workers is expensive, these milling machines can make top-notch parts with fewer people, which saves a lot of money.

Case Study: Boosting Efficiency in Auto Manufacturing with CNC

Let’s take a real-world example from the automotive industry. Consider “Hyper Racer”, a Melbourne based boutique race car manufacturer that faced the challenge of improving the efficiency of their production line as well as the performance of their racing vehicles.

They partnered with Rootech, a company specialising in CNC machining and high-precision manufacturing, to achieve this. Rootech’s expertise in high-precision technology was exactly what Hyper Racer needed.

Before increasing the utilisation of CNC technology, Hyper Racer relied on more traditional manufacturing methods, which was not only slower but also prone to errors that led to higher waste and increased costs.

The precision required for components utilised in the motorsport environment, like suspension components or engine ancillaries, meant that any discrepancy could lead to significant setbacks in manufacturing timeline, reduced performance and safety issues.

After shifting to a more extensive use of CNC machining, Hyper Racer noticed a series of substantial improvements. They were able to produce parts with such consistency and accuracy that the defect rate plummeted. They could also produce parts lights-out 24/7, thanks to the automation that CNC technology and robotics provided, significantly increasing their output.

This change helped them produce a more competitive product in a market that demands high-quality products and cost-efficiency.

Conclusion

In conclusion, CNC machining is a foundation of innovation in modern manufacturing. The real-world case of AutoCrafters illustrates its transformative power, showcasing significant enhancements in precision, efficiency, and cost-effectiveness.

Utilising CNC technology is not just an upgrade; it’s a leap into the future of production, setting new standards across industries.