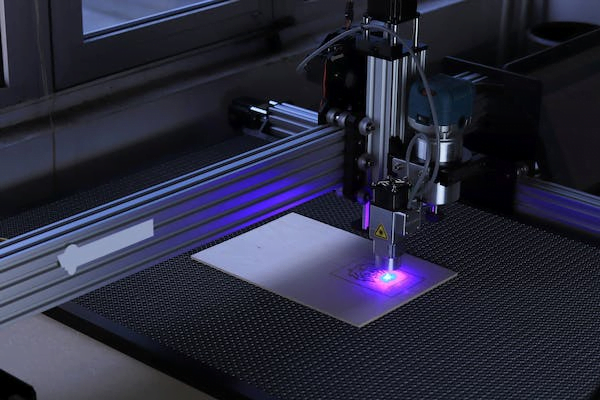

CNC is the abbreviation that refers to computer numerical control. CNC machining is the manufacturing process that creates the final product by removing material using a cutting tool, where computers play a significant role in guiding the motion of both the machine and the cutting tool to accomplish extremely accurate movements. Unlike human labor, the implementation of CNC machining enables the automation of the manufacturing process, improving precision and efficiency.

In this blog post, we will discuss the applications of CNC manufacturing in different industries worldwide. Let’s get in!

Industries That Use CNC Machining Processes

Various industries are using the CNC machining process to manufacture their new products.

The main industries are as follows:

- Aerospace industry

- Automotive industry

- Marine industry

- Electronic industry

- Smartphones industry

- Military and defense industry

- Healthcare industry

- Dental equipment industry

- Energy industry

- Jewelry, furniture, shoe industries

1. Aerospace Industry

CNC machining has been around for decades in the aerospace sector. Metal aircraft components are CNC machined due to the material properties as well as the high precision required, which is vital for safety-sensitive applications. Furthermore, the variety of technical metals compatible with CNC provides aircraft engineers with a wide array of possibilities.

2. Automotive Industry

CNC (Computer Numerical Control) manufacturing plays a pivotal role in the automotive industry by enhancing precision, efficiency, and production speed. CNC machines automate the fabrication of complex components, ensuring consistent quality and adherence to tight tolerances.

From engine parts to intricate components, CNC machining creates highly accurate components, allowing the improvement of vehicle performance and safety.

Additionally, CNC machining facilitates rapid prototyping and customization, allowing manufacturers to adapt quickly to design changes. This technology optimizes production processes, reduces waste, and ultimately enhances the overall competitiveness and innovation within the automotive sector.

3. Marine Industry

The marine sector heavily relies on high-quality craftsmanship to develop water transportation vessels that can move worldwide. Here are some of the elements made by CNC machining for the marine industry:

- Deck constructions

- Structures of the hull

- Trimmings and Joints

- Interior furniture such as Kitchen Countertop

- Cabinets for storing items

- Wraparound seating

4. Electronic Industry

CNC (Computer Numerical Control) manufacturing plays a crucial role in the electronic industry by enhancing precision and efficiency in producing electronic components. For example, the metal alloy housing of Apple products such as the Macbook and iPhone is manufactured by CNC milling machines and routers.

CNC applies not just to the external shell of consumer electronics items but also to their internal components.

- Electronic components

- PCBs

- Housings

- Jigs

5. Smartphones Industry

The bulk of smartphones available today on the market are built using CNC manufacturing techniques.

Here are some smartphone components created using CNC programming on CNC routers and CNC milling machines:

- Smartphone casings (metal and plastic)

- Cases for Smartphones

- Touch-sensitive displays

- Back glass panels

6. Defence and Military Industry

CNC machining is commonly used in the defense industry to prototype tough and durable items. Similarly to the aerospace industry, the defence sector heavily utilises CNC manufacturing to achieve highly accurate components with exceptional mechanical/thermal and electrical properties.

7. Healthcare Industry

CNC machining can be used on a variety of medically safe materials. Because the process is well suited for one-of-a-kind custom parts, it has numerous applications in the medical business.

Healthcare producers use CNC machines to make the following parts:

- Bone screws

- Bone plates

- Surgical equipment

- Cutters, holders and forceps

- Prosthetics

8. Energy Industry

The energy industry is extensive, comprising sub-sectors like oil and gas. In fact, with the expansion of green energy and renewable power resources, the energy business is a fast growing industry, partially thanks to the advancements in manufacturing technologies such as CNC machining.

9. Dental Equipment:

Moving to the dentistry industry in which the dentist equipment is made are the big consumers of CNC machined products. Dental industries produce a wide range of products with the help of CNC machining techniques.

Here are some examples of dental equipment produced via CNC machining:

- Dental implants

- Dental cap

- Bridgework

- Trays for orthodontics

- Crown

- Telescope crown

- Implants

10. Jewelry Industry

A jewelry CNC machine aids not only in creating and shaping metal jewelry but also in grinding and polishing objects. Some of the things produced using CNC systems in the jewelry industry include:

- Rings

- Molds

- Casting models

- Engravings

- Marble faceting

- Jewelry polishing

11. Shoe Industry

It makes metal molds used as dies to make the design seen on rubber soles. A CNC machine can also engrave the brand name and logo.

12. Furniture Industry

Depending on the project, a wide range of CNC machines are used in furniture manufacturing. A simple CNC lathe, for example, can be used to design hardwood legs for a dining table, and electrical discharge machining can be used to cut metal. Here are some examples of CNC furniture applications:

- Dining table legs

- Chair legs

- Metal frames

- Glass Cutting

- Polishing

- Engraving

13. Signage

The signage industry has changed significantly in terms of accessible designs and materials. Wood, plastic, aluminum, sheet metal, brass, acrylics, foam, engineering materials, and other common materials are used in this business.

14. Architecture and Designer

CNC machining aids in the completion of this task. Decor elements for architects and interior designers are also created using CNC machining. Based on the tasks, the design components and their characteristics can be greatly adjusted.

15. Food Industry

Regarding CNC machining, the food and beverage sectors aren’t the first to come to mind. Some examples of common applications include:

- Molds

- Die casting

- Food processing machine tools

- Bakeware

- Etching

16. Metal Fabrication Industry

Many secondary businesses rely on the metal fabrication industry. Large metal sheets are cut using CNC procedures such as wire EDM, laser, waterjet, and plasma cutting. Other CNC programs can mold these metal sheets into any shape required.

Conclusion

CNC manufacturing is widely used worldwide in the different industries we discussed above. A wide range of things and creations are being made by the CNC process that we can not put in one article. Its precision and efficiency drive innovation from aerospace to electronics, enabling diverse sectors to realize their full potential. CNC’s adaptability highlights its vital role in shaping the future of manufacturing across a spectrum of industries.