In manufacturing, understanding CNC machining is like unlocking the secret language of precision production. Imagine a process where computers take the lead, guiding machines to craft intricate parts with utmost accuracy. Here comes CNC (Computer Numerical Control) machining, a game-changer in modern industry.

In this blog post, we will understand the key components and basics of CNC machines. Let’s get in to explore!

Understanding CNC: Computer Numerical Control

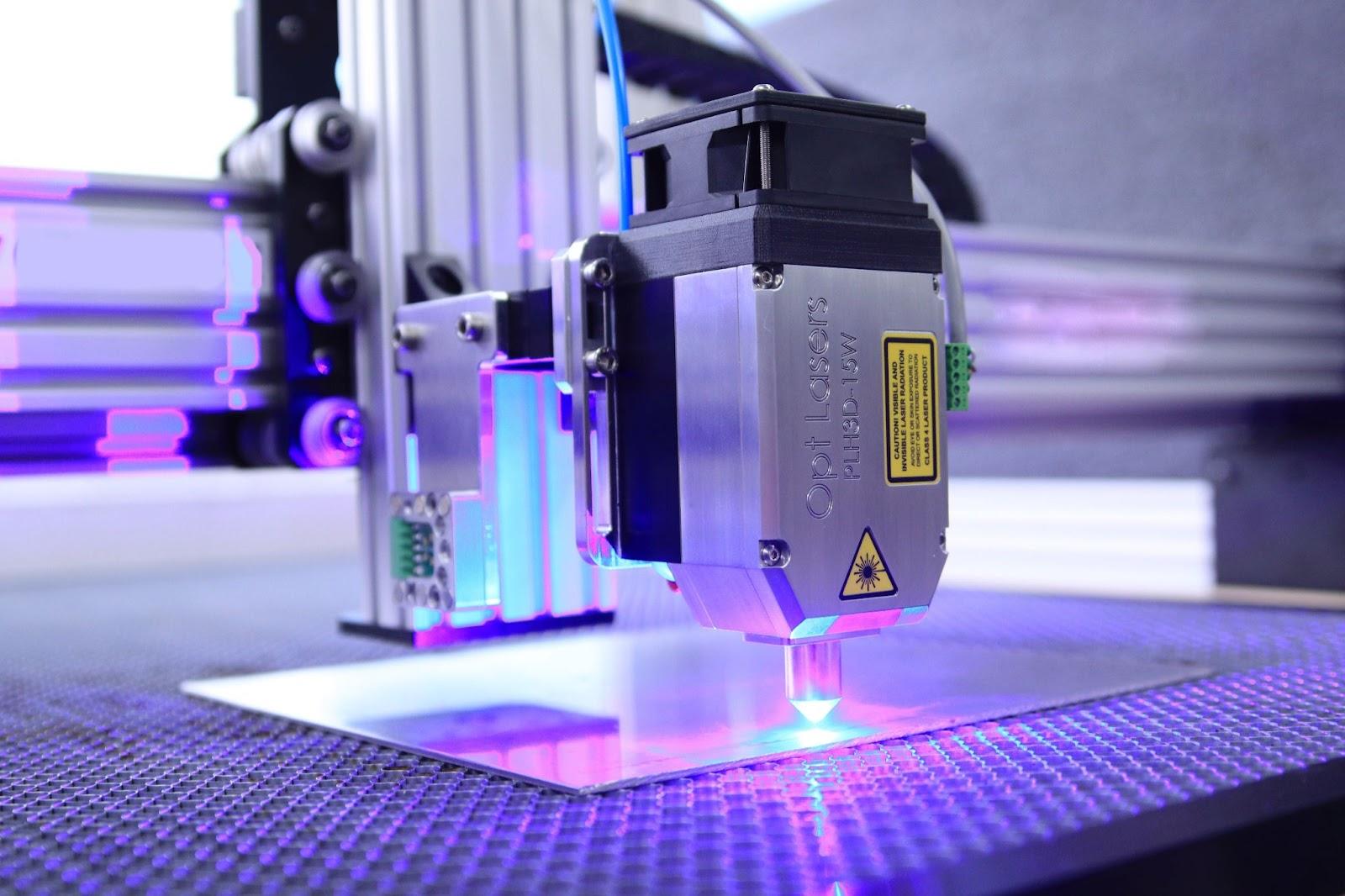

At its core, CNC machining relies on the power of Computer Numerical Control, where computers play a vital role in guiding machining tools to execute precise movements. Unlike manual operation, CNC machining automates manufacturing, enhancing accuracy and efficiency.

The foundation of CNC lies in its ability to interpret numerical data and translate it into precise, real-world actions.

Key Components of CNC Machines

Understanding the key components of CNC machines is crucial for anyone planning to incorporate CNC machining in their businesses.

- CNC Controller: This acts as the brain of the operation, interpreting the programmed instructions and translating them into specific movements.

- Motors and Drives: These components physically drive the machine’s motion, ensuring precise and controlled tool movements.

- Cutting Tools: The selection of appropriate cutting tools is vital, influencing the type of machining operations and the quality of the final product.

- Workholding Devices: These devices secure the machined material, ensuring stability and accuracy.

Types of CNC Machining

Here are some common types of CNC machining. Understanding these types are:

1. CNC Milling Machines

In CNC machining, milling machines stand tall as versatile workhorses, shaping materials with precision and consistency.

Let’s get into the intricacies of CNC milling to understand its functionality and applications.

How CNC Milling Works

At its core, CNC milling involves the removal of material layers from a workpiece to achieve the desired shape. A computerised controller does the process, interpreting instructions to guide the milling machine precisely. The cutting tool, spinning at high speeds, carves away material bit by bit, crafting the final product.

Applications and Industries Using CNC Milling

CNC milling finds its applications across a spectrum of industries. From aerospace to automotive and beyond, these machines excel in creating complex components with tight tolerances. Whether crafting prototypes or producing important and delicate parts at scale, CNC milling machines play a vital role in shaping modern manufacturing.

2. CNC Turning Machines

CNC turning machines play a crucial role in machining by enabling precision turning operations. Unlike milling, turning involves rotating a workpiece while a cutting tool shapes it into the desired form. CNC turning automates this process, offering enhanced accuracy and efficiency.

How CNC Turning Works

In CNC turning, the workpiece is clamped and rotated, allowing the cutting tool to remove material strategically. The CNC controller interprets programming instructions, precisely guiding the tool’s movements.

This method is particularly effective for creating cylindrical shapes, intricate contours, and threaded components.

Advantages

Its advantages include rapid production of complex parts, improved consistency, and the ability to work with diverse materials. Manufacturers often turn to CNC turning for creating components like shafts, bushings, and custom-designed parts with unparalleled accuracy.

Understanding the ins and outs of CNC turning machines opens up possibilities for crafting precise components with efficiency and reliability.

3. CNC Routers

CNC router machines stand out in CNC machining for their versatility, making them a favorite in woodworking and beyond. These machines operate on the same principles as other CNC devices but specialise in precision cutting, shaping, and carving materials like wood, plastic, and composites.

Common Uses in Woodworking

Woodworkers find CNC routers vital for intricate designs and detailed woodwork. These machines excel at creating precisely carved patterns, ornate furniture, and customised cabinetry. The ability to consistently reproduce intricate details makes CNC routers a go-to tool for woodworking professionals.

Applications and Advantages

While renowned in woodworking, CNC routers extend their capabilities to various industries. They’re employed in sign-making, where precision and detail are paramount.

Additionally, these machines find applications in creating molds for plastic and composite materials, showcasing their adaptability across different manufacturing domains.

With their user-friendly interface and broad applications, CNC routers continue to shape how we approach precision machining tasks.

Materials Used in CNC Machining

In CNC machining, the choice of materials plays a vital role in determining the success of a project. Different materials exhibit varying properties, affecting the machinability and end-product quality. Let’s get in!

Overview of CNC-Compatible Materials

CNC machines are versatile and can work with various materials, each with unique characteristics.

- Metals: Metals like aluminum, steel, titanium, and even brass are commonly employed for their strength, durability, and excellent machinability.

- Plastics: Materials such as ABS, acrylic, and nylon find applications in CNC machining due to their lightweight nature, versatility, and ease of machining.

- Composites: Fiberglass and carbon fiber composites balance strength and flexibility, making them suitable for specific applications, especially in the aerospace and automotive industries.

- Wood: Wood is a notable addition to CNC-compatible materials, offering a natural aesthetic appeal. CNC machining in wood is popular for creating intricate designs in furniture, prototypes, and artistic pieces.

Material Selection Considerations

- Strength and Durability: The material’s strength and durability are critical considerations depending on the intended use. Metals may be preferred for robust industrial components, while wood could be an ideal choice for decorative and artisanal projects.

- Machinability: Materials like aluminum and wood are known for their excellent machinability, facilitating faster production times and reduced tool wear. Other materials, such as hardened steel, may pose more challenges but offer unique properties.

Understanding the properties of these diverse materials ensures optimal performance from CNC machines. Whether crafting aerospace components, functional prototypes, or artistic wooden creations, the right material selection is crucial in CNC machining.

Conclusion

In manufacturing, grasping the intricacies of CNC machining unlocks the gateway to precision production. From the foundational understanding of Computer Numerical Control (CNC) to exploring the key components and various types of CNC machines, this guide is a compass for beginners.