With the advancement of different production and manufacturing techniques, 3D scanning is something that has taken up the market and is here to stay!

3D scanning, which is an underground phenomenon that has grown to become a new paradigm in the era of precision and innovation, is a game changer redefining industries. It has reinvented design processes and re-imagined how man interacts with his physical environment.

This tech creates highly detailed models of objects that help in analysing virtually by measuring them precisely, and the digital realm allows for research and replication.

The Efficiency of 3D Scanning in Manufacturing and Design

This cutting-edge tool bypasses the limitations of the traditional manufacturing process and boosts efficiency by channelling the product development and monitoring process through the digital workflow.

Quality Control and Inspection

Quality control and inspection are areas in which 3D scanning is very critical, owing to excellent measurements of manufacturing items with high precision. The production process using the scan data as a basement for detection and assurance of the quality standards is where their CAD models come in handy.

Reverse Engineering and Prototyping

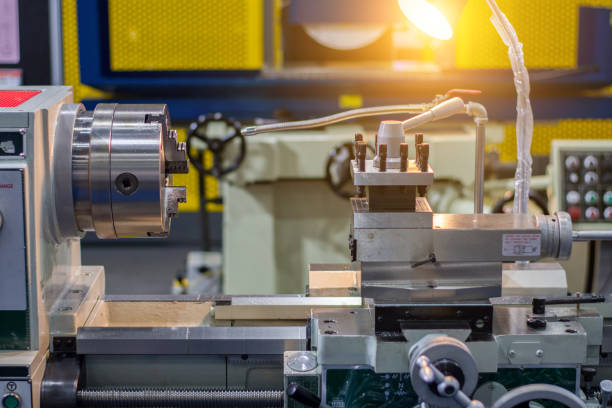

The capability to digitally scan and analyse physical parts with very precise detail is something that the world of reverse engineering offers as a crucial tool, and 3D scanning represents the best ways to achieve this.

Whether slowly breaking up the intricacies of legacy components or modern machinery, 3D scanning helps to efficiently transition from reality to the digital world, providing a solid platform to power innovations.

Customisation and Personalisation

Basically, the customisation process in industry is aimed to provide specific solutions to whoever it is by adjusting products they use to meet their individual needs. In this case, 3D scanning is crucial due to its ability to create an accurate and fully digital model of physical things or surrounding environments.

Whatever may provide the highest level of detail of complex parts or the greatest levels of accuracy in mapping out the dimensions of specific tools, 3D scanning provides that for the industry that remains specialised.

Challenges and Solutions in Implementing 3D Scanning

Even though 3D scanning has allowed it to shift towards better efficiency, speed, and accuracy, its implementation still faces challenges.

Data Processing and Management Challenges

One of the major challenges faced while 3D scanning is in data processing and management.

The continuous output of high-volume and complex data, which has to be flawlessly accurate, makes this task even harder, and apart from dealing with environmental factors and calibration errors, it greatly affects system limitations.

To overcome these hurdles, companies rely on mesh manipulation and reverse engineering softwares, such as Geomagic Design X, to aid in noise reduction as well as to provide a design platform for reverse engineering the captured 3D data or to utilise it for further downstream development work. Innovative solutions like cloud-based platforms and AI-driven automation are also capable of accelerating and simplifying data processing, enabling for prompt data analysis and decision-making.

Cost and Return on Investment Analysis

Cost analysis of the project poses a complicated challenge in the implementation of the technology because the high initial cost is a main factor in the purchase of high-quality scanning equipment and software.

However, the solution to this is that businesses can reduce the negative impact of these effects through a rigorous ROI evaluation, and the factors to which one should pay attention in advance are increased productivity, reduced prototyping iterations, and improved product quality.

Future Trends and Innovations in 3D Scanning

As 3D scanning is only going to be more and more integrated in the design and manufacturing workflow, the trend is that both hardware and software will continue to develop and become more financially accessible and provide an ever better user experience.

Advancements in Portable and Handheld Scanning Devices

The future-generation 3D scanning devices will be smaller, light as a feather, and also ultra-portable hence much easier to handle. The further advanced sensor technology and computational power will make handheld 3D scanners in the future more accurate and faster than those that currently exist, ensuring that a user will not only be able to capture even the tiniest of the details, but will be able to do so in a very short time efficient manner.

Integration of Artificial Intelligence and Machine Learning

AI inspires the development of algorithms, which, subsequently, will be capable of 3D scanning with an even higher degree of accuracy as well as automatically perceive and analyse data in real time. Imagine a future where scanners using the latest 3D technology are connected with AI that can detect objects in real time, foresee problems, and make the requisite parameter adjustments instantly to obtain the best results.

3D scanning has evolved over the years and is a new trend. It has yet to develop more in the future as more cutting-edge technologies will be integrated into it.