At Roo Technologies, we manufacture high-quality, precision-made prototypes and production parts that turn ideas into reality so you can meet your organisation’s ambitious goals. CNC machine processes offer significant advantages in both prototyping and mass production, providing automated control over machining tools and enabling scalable business operations. Through expert craftsmanship, cutting-edge CNC machining technology in Melbourne and a passion for precision, you enjoy unparalleled engineering solutions.

Years of Experience

Clients Supported (Local & Global)

Prototypes Manufactured

Components Expertly Crafted

“Roo Technologies were able to offer a complete package for all of our design and manufacturing requirements. From initial design consultation, 3D scanning, rapid prototyping and final production of our CNC machined components, the service and support offered by Giovanni and his team throughout was exceptional.”

WE’RE PERFECT FOR YOU IF YOU WANT TO:

Roo Technologies is a Melbourne-based CNC machining company boasting over a decade of experience in transforming complex designs into tangible, high-quality products.

CNC machines offer advanced capabilities in sectors like aerospace, automotive, and healthcare, enabling businesses to streamline production, reduce human errors, and produce complex parts with high accuracy.

More than a cnc manufacturing company, we believe every great product starts with a great idea and understand that each meticulously machined component contributes to your overall success. As your partner in creating something meaningful and impactful, our goal isn’t to be the cheapest machining partner because the components we craft are part of something greater than us.

Whatever your needs and goals, we approach every job with the same mission: combining precise attention-to-detail with cutting-edge machining technology to ensure your big picture vision is supported by the perfection of its parts.

At Roo Technologies, your idea is our blueprint and your vision is our commitment.

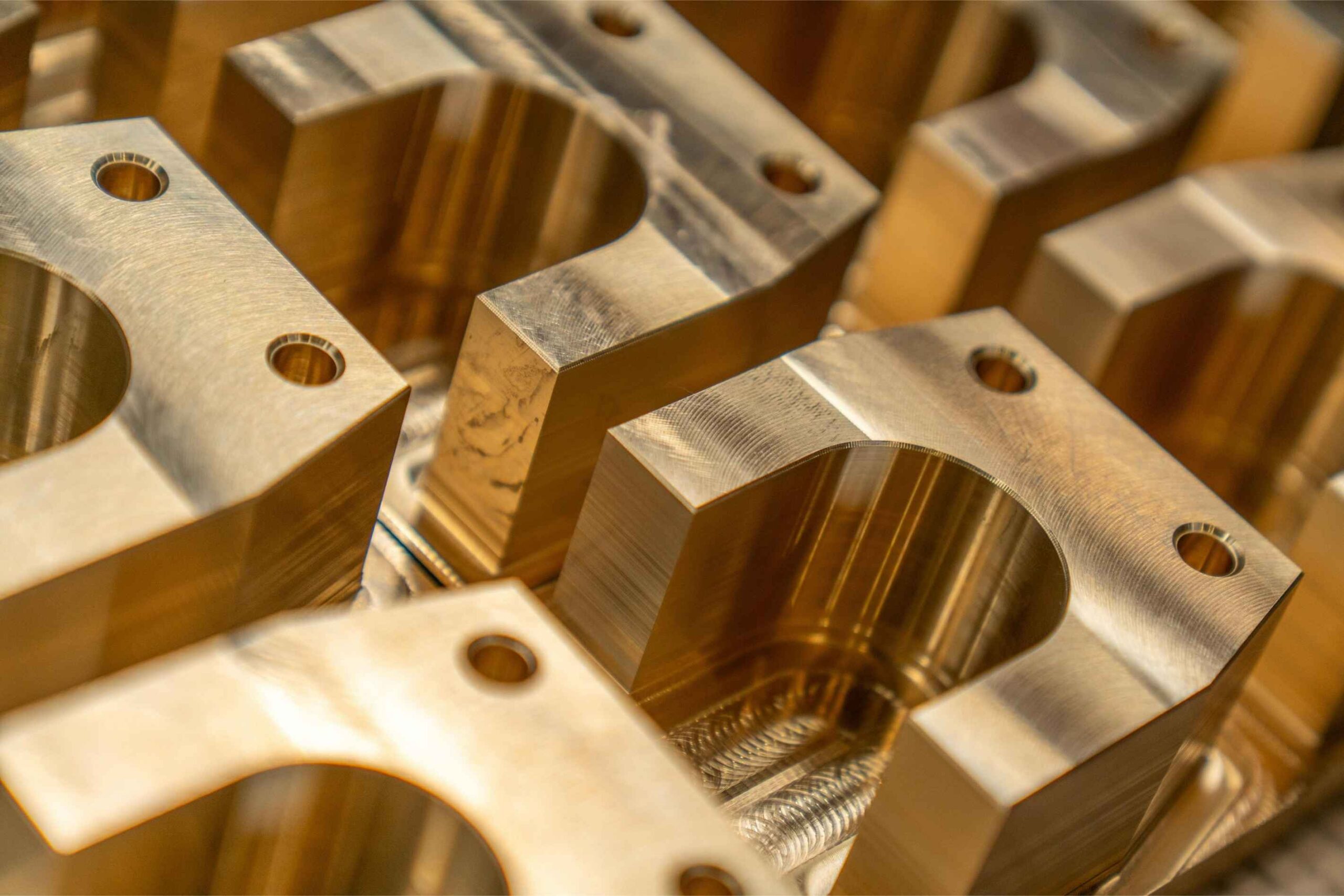

CNC machining is capable of working with a diverse range of materials, including metals, plastics, and composites. The selection of material is crucial and depends on the specific application and the desired properties of the final product. Common materials used in CNC machining include aluminum, stainless steel, brass, titanium, and copper. Additionally, various plastics such as ABS, ASA, and PC are frequently machined to meet specific requirements. This flexibility in material choice allows CNC machining to cater to a wide spectrum of industries and applications, ensuring the production of high-quality, durable components.

Ready to accelerate your production of components, progress your latest prototype, or support your CNC manufacturing needs? Reach out with inquiries, project ideas or to organise a 100% obligation-free consultation. We are committed to provide CNC machining services with precision and quality.

CNC machining is a sophisticated manufacturing process that leverages computer numerical control (CNC) to create intricate 3D items. This process involves the use of computer-controlled machines to meticulously remove material from a workpiece, shaping it into the desired form and design. The versatility of CNC machining allows it to produce a wide array of products, ranging from simple parts to highly complex components. By utilising precise computer numerical control, this manufacturing process ensures high accuracy and consistency, making it an essential technique in modern manufacturing.

We serve a diverse range of industries, including automotive, aerospace, medical, technology, and manufacturing sectors. Our precision machining and engineering solutions are tailored to meet the unique needs and standards of each industry, ensuring unparalleled service quality and product performance.

We have the capability to work with a wide variety of materials including aluminium, stainless steel, brass, copper and more. Our versatile machining services ensure we can accommodate your specific project needs.

Project timelines vary as they are custom-tailored to the complexity and volume of each individual project. We guarantee that our dedicated engineers will respond to your inquiries and provide an estimated project timeline within 24 hours of your request.

Absolutely! We excel in offering comprehensive design and prototyping services for your parts. Our team of experts will work closely with you to transform your concept into a functional prototype.

While we’re based in Melbourne, Australia, we proudly serve clients across the globe. Our extensive shipping network allows us to deliver high-quality machined parts anywhere in the world. Whether you’re local or international, Roo Tech is committed to meeting your CNC machining needs.

Rootech: CNC Machining Melbourne, expertly transforming your visions into meticulously engineered realities, locally and internationally.